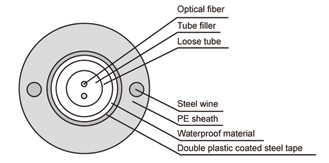

OUTDOOR FIBER OPTICAL CABLE (GYXS)

Description :

In the structure of Model GYXS optical cable, the single mode or multimode optical fibers are jacketed by loose tube and the tube is made of high modulus polyester. Inside the tube, it is full of water-proof filling compound, in which no elemental hydrogen could be detected. Outside the loose tube, it is wrapped longitudinally by a layer of both sides plastic coated ripple steel tape and the water-proof material between the steel tape and loose tube is used to ensure compact optical cable structure and longitudinal water-proof. There are two parallel steel wires on the two sides of the loose tube and they are sheathed by PE to form an optical cable.

In the structure of Model GYXS optical cable, the single mode or multimode optical fibers are jacketed by loose tube and the tube is made of high modulus polyester. Inside the tube, it is full of water-proof filling compound, in which no elemental hydrogen could be detected. Outside the loose tube, it is wrapped longitudinally by a layer of both sides plastic coated ripple steel tape and the water-proof material between the steel tape and loose tube is used to ensure compact optical cable structure and longitudinal water-proof. There are two parallel steel wires on the two sides of the loose tube and they are sheathed by PE to form an optical cable.

Application :

- The medium density PE sheath features perfect mechanical tensile strength, weatherproof, abrasive resistance and good environmental stress cracking performance

- The longitudinally wrapped both side plastic coated steel tapes and water-proof tape could effectively prevent tube from shrinking and improve optical cable waterproof, penetration resistance and moisture-proof

- It is convenient in construction as its small diameter, light weight and perfect performance-price ratio

- The remaining length of optical fiber is controlled precisely to ensure perfect mechanical performance nad temperature characteristics of optical cable

- The loose tube material itself has perfect hydrolysis resistance and high strength. The special filling paste inside the loose tube is used to protect the optical fiber

Product Figure :

OUTDOOR FIBER OPTICAL CABLE (GYTA)

Description :

- Available in GYTA type

- The remaining length of optical fiber is controlled precisely to ensure perfect tensile strength and temperature characteristics of optical cable

- The loose tube material itself has perfect hydrolysis resistance and high strength. The special filling paste inside the loose tube is used to protect the optical fiber

- Perfect flexibility and pressing resistance

- PE sheath features perfect UV resistant performance and environmental stress cracking resistance

Application :

- Waterproof performance of optical cable is ensured by following measures : Single piece of steel wire center reinforcement

- Special waterproof compound filled inside the loose tube 100% filled cable core :

- Perfect moisture-proof capability of the moisture-proof plastic coated aluminum tape and both side plastic coated steel tape :

- Perfect waterproof material could prevent optical cable from longitudinal water penetration

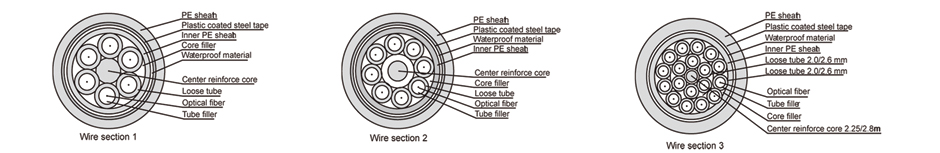

Product Figure :

| No of fiber cable core | Diameter of steel core (mm) | Plastic coated steel tape (mm) | Diameter of the loose tube (mm) | Core of the loose tube | Filler core No. | Diameter of fiber cable (mm) | Weight of the fiber (Kg/Km) | (Short term/long term) allowable tension (N) | Allowable press force N/100mm |

| 4-6 | 1.6 | / | 1.5/2.1 | 1 | 4 | 10.2 | 95 | 600/1500 | 1000 |

| 8-12 | 1.6 | / | 1.5/2.1 | 2 | 3 | 10.2 | 95 | 600/1500 | 1000 |

| 14-18 | 1.6 | / | 1.5/2.1 | 3 | 2 | 10.2 | 95 | 600/1500 | 1000 |

| 20-24 | 1.6 | / | 1.5/2.1 | 4 | 1 | 10.2 | 95 | 600/1500 | 1000 |

| 26-30 | 1.6 | / | 1.5/2.1 | 5 | 0 | 10.2 | 95 | 600/1500 | 1000 |

| 32-36 | 2.25 | / | 1.5/2.1 | 6 | 0 | 11.6 | 139 | 1000/3000 | 1000 |

| 38-42 | 2.25 | 3.7 | 1.5/2.1 | 7 | 1 | 12.8 | 164 | 1000/3000 | 1000 |

| 44-48 | 2.25 | 3.7 | 1.5/2.1 | 8 | 0 | 12.8 | 164 | 1000/3000 | 1000 |

| 50-60 | 2.25 | 2.8 | 2.0/2.6 | 5 | 1 | 12.8 | 164 | 1000/3000 | 1000 |

| 62-72 | 2.25 | 2.8 | 2.0/2.6 | 6 | 0 | 12.8 | 164 | 1000/3000 | 1000 |

| 74-84 | 2.25 | 4.5 | 2.0/2.6 | 7 | 1 | 14.6 | 214 | 1000/3000 | 1000 |

| 86-96 | 2.25 | 4.5 | 2.0/2.6 | 8 | 0 | 14.6 | 214 | 1000/3000 | 1000 |

| 98-108 | 2.25 | 6.1 | 2.0/2.6 | 9 | 1 | 17 | 262 | 1000/3000 | 1000 |

| 110-120 | 2.25 | 6.1 | 2.0/2.6 | 10 | 0 | 17 | 262 | 1000/3000 | 1000 |

| 122-132 | 2.25 | 8.1 | 2.0/2.6 | 11 | 1 | 19.5 | 325 | 1000/3000 | 1000 |

| 134-144 | 2.25 | 8.1 | 2.0/2.6 | 12 | 0 | 19.5 | 325 | 1000/3000 | 1000 |

| 146-216 | 19.5 | 330 | 1000/3000 | 1000 | |||||

| Order Information | ||

| Part number | Description | Standard Color |

| LNCM02-*-62.5 | Multi Mode Out Optical Cable | Black |

| LNCS02-* | Single Mode Out Optical Cable | Black |

| LNCM03-*-62.5 | Multi Mode Out Optical Cable | Black |

| LNCS03-* | Single Mode Out Optical Cable | Black |

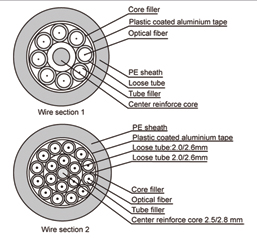

OUTDOOR FIBER OPTICAL CABLE (GYTS)

Description :

- Available in GYTS type

- Waterproof performance of optical cable is ensured By following measures : Single piece of steel wire center reinforced core

- Special waterproof compound filled inside the loose tube complete filled cable core

- Moisture-proof layer of both side plastic coated steel tape : Perfect waterproof material could prevent optical cable from longitudinal water penetration

Application :

- The remaining length of optical fiber is controlled precisely to ensure perfect tensile strength and temperature characteristics of optical cable

- The loose tube material itself has perfect hydrolysis resistance and high strength. The special filling paste inside the loose tube is used to protect the optical fiber

- Perfect flexibility and pressing resistance

Product Figure :

| No of fiber cable core | Diameter of steel core (mm) | Plastic coated steel tape (mm) | Diameter of the loose tube (mm) | Core of the loose tube | Filler core No. | Diameter of fiber cable (mm) | Weight of the fiber (Kg/Km) | (Short term/long term) allowable tension (N) | Allowable press force N/100mm |

| 4-6 | 1.5 | / | 1.5/2.1 | 1 | 4 | 11.8 | 138 | 600/1500 | 1000 |

| 8-12 | 1.5 | / | 1.5/2.1 | 2 | 3 | 11.8 | 138 | 600/1500 | 1000 |

| 14-18 | 1.5 | / | 1.5/2.1 | 3 | 2 | 11.8 | 138 | 600/1500 | 1000 |

| 20-24 | 1.5 | / | 1.5/2.1 | 4 | 1 | 11.8 | 138 | 600/1500 | 1000 |

| 26-30 | 1.5 | / | 1.5/2.1 | 5 | 0 | 11.8 | 138 | 600/1500 | 1000 |

| 32-36 | 2.25 | / | 1.5/2.1 | 6 | 0 | 13.0 | 170 | 1000/3000 | 1000 |

| 38-42 | 2.25 | 3.7 | 1.5/2.1 | 7 | 1 | 14.0 | 200 | 1000/3000 | 1000 |

| 44-48 | 2.25 | 3.7 | 1.5/2.1 | 8 | 0 | 14.0 | 200 | 1000/3000 | 1000 |

| 50-60 | 2.25 | 2.8 | 2.0/2.6 | 5 | 1 | 14.0 | 200 | 1000/3000 | 1000 |

| 62-72 | 2.25 | 2.8 | 2.0/2.6 | 6 | 0 | 14.0 | 200 | 1000/3000 | 1000 |

| 74-84 | 2.25 | 4.5 | 2.0/2.6 | 7 | 1 | 15.6 | 245 | 1000/3000 | 1000 |

| 86-96 | 2.25 | 4.5 | 2.0/2.6 | 8 | 0 | 15.6 | 245 | 1000/3000 | 1000 |

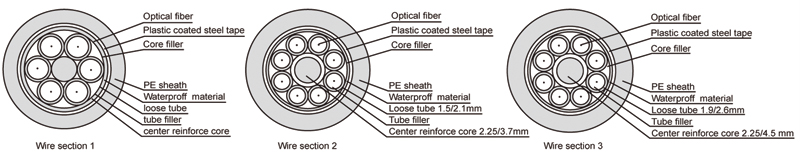

OUTDOOR FIBER OPTICAL CABLE (GYTA53)

Description :

- Available in GYTA53 type

- The remaining length of optical fiber is controlled precisely to ensure perfect tensile strength and temperature characteristics of optical cable

- The loose tube material itself has perfect hydrolysis resistance and high strength. The special filling paste inside the loose tube is used to protect the optical fiber

- Perfect flexibility and pressing resistance

- PE sheath features perfect UV resistant performance and environmental stress cracking resistance

Application :

- Waterproof performance of optical cable is ensured by following measures : Single piece of steel wire center reinforcement

- Special waterproof compound filled inside the loose tube 100% filled cable core

- Perfect moisture-proof capability of the moisture-proof plastic coated aluminum tape and both side plastic coated steel tape

- Perfect waterproof material could prevent optical cable from longitudinal water penetration

Product Figure :

| No of fiber cable core | Diameter of steel core (mm) | Plastic coated steel tape (mm) | Diameter of the loose tube (mm) | Core of the loose tube | Filler core No. | Diameter of fiber cable (mm) | Weight of the fiber (Kg/Km) | (Short term/long term) allowable tension (N) | Allowable press force N/100mm |

| 4-6 | 1.6 | / | 1.5/2.1 | 1 | 4 | 14.8 | 256 | 600/1500 | 3000 |

| 8-12 | 1.6 | / | 1.5/2.1 | 2 | 3 | 14.8 | 256 | 600/1500 | 3000 |

| 14-18 | 1.6 | / | 1.5/2.1 | 3 | 2 | 14.8 | 256 | 600/1500 | 3000 |

| 20-24 | 1.6 | / | 1.5/2.1 | 4 | 1 | 14.8 | 256 | 600/1500 | 3000 |

| 26-30 | 1.6 | / | 1.5/2.1 | 5 | 0 | 14.8 | 256 | 600/1500 | 3000 |

| 32-36 | 2.25 | / | 1.5/2.1 | 6 | 0 | 14.8 | 256 | 1000/3000 | 3000 |

| 38-42 | 2.25 | 3.7 | 1.5/2.1 | 7 | 1 | 16.8 | 304 | 1000/3000 | 3000 |

| 44-48 | 2.25 | 3.7 | 1.5/2.1 | 8 | 0 | 16.8 | 304 | 1000/3000 | 3000 |

| 50-60 | 2.25 | 2.8 | 2.0/2.6 | 5 | 1 | 16.8 | 306 | 1000/3000 | 3000 |

| 62-72 | 2.25 | 2.8 | 2.0/2.6 | 6 | 0 | 16.8 | 306 | 1000/3000 | 3000 |

| 74-84 | 2.25 | 4.5 | 2.0/2.6 | 7 | 1 | 18.9 | 366 | 1000/3000 | 3000 |

| 86-96 | 2.25 | 4.5 | 2.0/2.6 | 8 | 0 | 18.9 | 366 | 1000/3000 | 3000 |

| 98-108 | 2.25 | 6.1 | 2.0/2.6 | 9 | 1 | 21.5 | 429 | 1000/3000 | 3000 |

| 110-120 | 2.25 | 6.1 | 2.0/2.6 | 10 | 0 | 21.5 | 429 | 1000/3000 | 3000 |

| 122-132 | 2.25 | 8.1 | 2.0/2.6 | 11 | 1 | 22.3 | 488 | 1000/3000 | 3000 |

| 134-144 | 2.25 | 22.3 | 2.0/2.6 | 12 | 0 | 22.3 | 488 | 1000/3000 | 3000 |

| 146-216 | 22.3 | 500 | 1000/3000 | 3000 | |||||

| Order Information | ||

| Part number | Description | Standard Color |

| LNCM04-*-62.5 | Multi Mode Out Optical Cable | Black |

| LNCS04-* | Single Mode Out Optical Cable | Black |

| LNCM05-*-62.5 | Multi Mode Out Optical Cable | Black |

| LNCS05-* | Single Mode Out Optical Cable | Black |

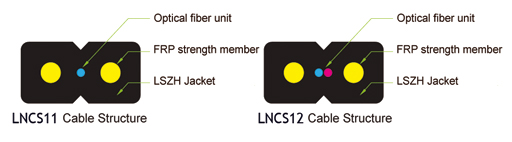

BOW – TYPE DROP CABLE (GJXFH)

Description :

The optical fiber unit is positioned in the center. Two parallel Fiber Reinforced Plastic (FRP) are placed at the two sides. Then, the cable is completed with a black or color LSZH sheath.

The optical fiber unit is positioned in the center. Two parallel Fiber Reinforced Plastic (FRP) are placed at the two sides. Then, the cable is completed with a black or color LSZH sheath.

Application :

- Special low-bend-sensitivity fiber provides high bandwidth excellent and excellent communication transmission property

- Two parallel FRP strength members ensure good perform crush resistance to protect the fiber

- Simple Structure, light weight and high practicability

- Novel flute design, easily strip and splice simplify the installation and maintenance

- Low smoke, zero halogen and flam retardant sheath.

Product Figure :

| Technical Parameters | |||||

| Fiber Count | Cable Size (mm) | Cable Weight (Kg/Km) | Tensile Strength Long/Short Term (n) | Crush Resistance Long/Short Term (N/100mm) | Bending Radius Static/Dynamic (mm) |

| 1 | (2.0 + 0.1) x (3.0 + 0.1) | 8 | 40/80 | 500/1000 | 15/30 |

| 2 | (2.0 + 0.1) x (3.0 + 0.1) | 8.5 | 40/80 | 500/1000 | 15/30 |

| Order Information | ||

| Part number | Description | Standard Color |

| LNCS11-1-LSZH | Bow-type drop cable, single mode, simplex | Black |

| LNCS11-2-LSZH | Bow-type drop cable, single mode, duplex | Black |

| LNCM11-1-LSZH | Bow-type drop cable, Multi mode, simplex | Black |

| LNCM11-2-LSZH | Bow-type drop cable, Multi mode, duplex | Black |

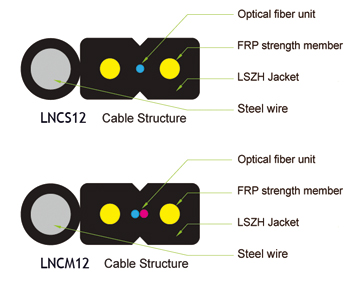

SELF – SUPPORTING BOW – TYPE DROP CABLE (GJYXFCH)

Description :

The optical fiber unit is positioned in the center. Two parallel Fiber Reinforced Plastic (FRP) are placed at the two sides. A steel wire as the additional strength member is also applied. Then, the cable is completed with a black or color LSZH sheath.

The optical fiber unit is positioned in the center. Two parallel Fiber Reinforced Plastic (FRP) are placed at the two sides. A steel wire as the additional strength member is also applied. Then, the cable is completed with a black or color LSZH sheath.

Application :

- Special low-bend-sensitivity fiber provides high bandwidth excellent and excellent communication transmission property

- Two parallel FRP strength members ensure good perform crush resistance to protect the fiber

- Single steel wire as the additional strength member ensures good performance of tensile strength.

- Simple Structure, light weight and high practicability

- Novel flute design, easily strip and splice simplify the installation and maintenance

- Low smoke, zero halogen and flam retardant sheath.

Product Figure :

| Technical Parameters | |||||

| Fiber Count | Cable Size (mm) | Cable Weight (Kg/Km) | Tensile Strength Long/Short Term (n) | Crush Resistance (N/100mm) | Bending Radius Static/Dynamic (mm) |

| 1 | (2.0 + 0.1) x (5.2 + 0.1) | 20 | 300/600 | 2200 | 15/30 |

| 2 | (2.0 + 0.1) x (5.2 + 0.1) | 20 | 300/600 | 2200 | 15/30 |

| Order Information | ||

| Part number | Description | Standard Color |

| LNCS12-1-LSZH | Self-Supporting Bow-type drop cable, single mode, simplex | Black |

| LNCS12-2-LSZH | Self-Supporting Bow-type drop cable, single mode, duplex | Black |

| LNCM12-1-LSZH | Self-Supporting Bow-type drop cable, Multi mode, simplex | Black |

| LNCM12-2-LSZH | Self-Supporting Bow-type drop cable, Multi mode, duplex | Black |